Plasma is a gaseous material that is separated from an atomic molecule and emits light with electricity flowing, and has the highest state in its transition, non-uniformity, and energy density than any other substance. The use of plasma has been used industrially for semiconductor, space, and mining industries. And most of these plasmas are plasmas in vacuum. The main reason for using vacuum is that it is easy to generate plasma in vacuum. Atmospheric plasma literally means plasma in atmospheric pressure atmosphere. The atmospheric pressure plasma is the gas in which the electrons fall from the atom or molecule in the atmospheric pressure state and the electricity flows and shines. The atmospheric pressure plasma is the gas in which the electrons fall from the atom or molecule in the atmospheric pressure state and the electricity flows and shines.

Atmospheric plasma can be divided into low temperature plasma and thermal equilibrium plasma. Low temperature plasma is a low temperature plasma with a large difference between plasma gas temperature and electron temperature. Thermal plasma is a plasma with a similar electron temperature and gas temperature. Industrially, thermal plasma can be obtained from thousands to tens of thousands of degrees. A typical example of low temperature plasma is DBD discharge plasma, and arc welding plasma is a representative example of thermal plasma.

The plasma is electrically generated and thus can generate atmospheric pressure plasma of a different kind.

According to the electrical method, it can be divided into direct current and alternating current (including pulse) and can be divided into MF(Medium frequency), RF(Radio frequency), MW(Microwave) etc.

Most of the direct current plasma at atmospheric pressure is used to make arc plasma. The plasma discharge by the alternating current can be classified according to the frequency. The MF (1~100kHz) can generate the plasma as the low frequency with the DBD discharge. The plasma generated at this time is a low temperature plasma and can be applied to thin films, cleaning, coatings, etc. The thermal plasma by the low temperature plasma generation by DBD and ICP can be occurred as the high frequency of the RF (2~1000MHz). In the case of low temperature plasma, it is available for thin films, cleaning, coatings, etc. and the plasma density is high. In case of ICP, thermal plasma is generated. At this time, the temperature of plasma is more than Mando, but there is a limit to the type of gas that can generate plasma. The application of this is diamond coating.

MW(microwave: 2~300GHz) is mainly used to make thermal plasma and is characterized by no electrode and gas type. Applications include the treatment of toxic gases and diamond coating.

DBD can be divided into two types according to the power frequency, namely low frequency and high frequency. In the case of low-frequency DBD, it is also called “silent” or “atmospheric-pressure-glow discharge”, and there is a dielectric barrier in at least one of the two electrodes. The gap interval is about the number mm and voltage is about 5~20kV The generation of plasma is obtained through the simultaneous series (the overall micro-arcs) of the micro-arcs maintained for 10~100ns. These micro-arcs or streamers are discharges of about 100 μm in diameter. The temperature of the former is known as 1 to 10eV.

In the case of high frequency DBD, the I-V curve of the typical low discharge appears and the plasma is maintained at hundreds of V. The main gas is the inert gas Ar, He etc. are used. The micro-arcs appearing at low frequency are not generated and the plasma density is high. The temperature of the electron is known as 1 to 3eV.

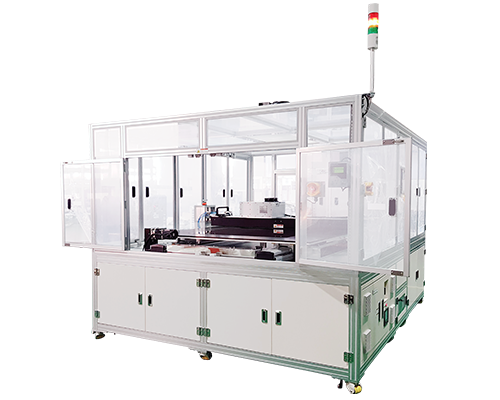

Diagnosis and application of atmospheric pressure plasma is the most difficult field to see easily. The meaning of being easy is that you can feel plasma directly. It is the temperature of the plasma as an example of easy diagnosis. In the case of low temperature plasma, you can directly touch it by hand, and paper does not burn even if you put it in plasma. In the case of thermal plasma, it is too hot to see the plasma directly, and when the spoon is put into the plasma, it melts quickly. However, it is not difficult to get plasma density, plasma sheath, electron energy distribution function, or electron energy that shows the basic characteristics of plasma by going a little deeper. This is based on plasma theory, and the theory of atmospheric pressure plasma is not yet systematized. Application of atmospheric pressure plasma is a field that is engaged with the diagnosis of plasma. If you do not know the input, you can not make a proper interpretation even if the output comes out. Currently, most plasma applications in Korea are trial and error. However, it is qualitatively different from trial and error like diagnosis. The application of atmospheric pressure plasma has already begun to be emphasized in economic and efficient aspects, and above all, it is important to meet the most efficient conditions of plasma when it is encountered by automation process. From here, the application of plasma is combined with the diagnosis of plasma. As with the diagnosis of vacuum plasma, the diagnosis of atmospheric pressure plasma is a necessary field in the application of atmospheric pressure plasma in the future.

FPCB consists of a PI coverlay film + Cu terminal (Ni plating).

The produced FPCB material body is often inconsistent with the required quality during chip bonding due to natural oxidation coating of the metal part or organic contamination. This naturally causes an increase in defect rate, a decrease in production yield, and a decrease in quality in the ACF bonding process.

For the purpose of improving ACF bonding power with the removal of organic matter from PI film and terminal, we need to use our plasma using Algon glow discharge, not ordinary atmospheric pressure plasma.

Low voltage, low power, no sputtering of the electrode itself, no particle generation, and low discharge voltage algons to ensure uniformity. If you use only oxygen or nitrogen, you can not use glow discharge, and you can generate arc demage and heat demise.

Oxygen plasma is used with algon, but direct plasma without arc discharge is treated in FPCB micropattern to provide yield, quality improvement, and bonding strength of ACF bonding.